Food Coating on:

[Wikipedia]

[Google]

[Amazon]

Coating is an process that consists of applying a liquid or a powder into the surface of an edible product to convey new (usually sensory) properties.

Coating is an process that consists of applying a liquid or a powder into the surface of an edible product to convey new (usually sensory) properties.

File:ধানের মুড়কি (Murki from paddy).jpg, Sugar-coated rice

Image:IQF_Frozen_Vegetable_Sauce_Coated.jpg,

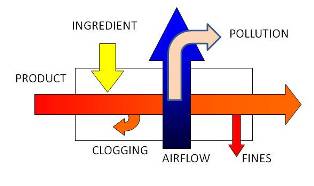

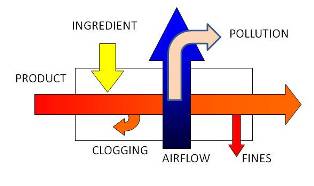

A coating process can be broken into the following elements:

* Inputs: base product, additives and ingredients

* Additional flows: air as a carrier of product or ingredient, or for drying, energy in a mechanical (agitation, transfer, friction) or a thermal form (convection, conduction or radiation heating)

* Outputs: end product, excess of coating ingredient, lost or to be recycled

Collaterals occur along the process:

* Breakage of product

* Generation of ''fines'' (small particles)

* Agglomeration of products

* Clogging of system surfaces with product or ingredient

* Airborne pollution, volatile organic component

These effects generally are to be avoided unless the end product is made more desirable.

Parameters affecting the system are listed by origin:

This first set of criteria governs the choice of the coating ingredient. The coating consists either in a single ingredient or a mix. This mix has different physical forms: solution, emulsion, suspension, powder, etc. It has its own characteristics. In addition, a fluid may be required such as spraying, cooling, heating or drying air.

The combination of the above characteristics drives the choice of the process principle. It has then to be precisely described.

The selection of the proper process and its control rely on the gathering of precise and reliable information.

A coating process can be broken into the following elements:

* Inputs: base product, additives and ingredients

* Additional flows: air as a carrier of product or ingredient, or for drying, energy in a mechanical (agitation, transfer, friction) or a thermal form (convection, conduction or radiation heating)

* Outputs: end product, excess of coating ingredient, lost or to be recycled

Collaterals occur along the process:

* Breakage of product

* Generation of ''fines'' (small particles)

* Agglomeration of products

* Clogging of system surfaces with product or ingredient

* Airborne pollution, volatile organic component

These effects generally are to be avoided unless the end product is made more desirable.

Parameters affecting the system are listed by origin:

This first set of criteria governs the choice of the coating ingredient. The coating consists either in a single ingredient or a mix. This mix has different physical forms: solution, emulsion, suspension, powder, etc. It has its own characteristics. In addition, a fluid may be required such as spraying, cooling, heating or drying air.

The combination of the above characteristics drives the choice of the process principle. It has then to be precisely described.

The selection of the proper process and its control rely on the gathering of precise and reliable information.

The influence of some phenomena and their parameters is critical: crystallisation, water removal (drying), glass transition, viscosity, or surface tension.

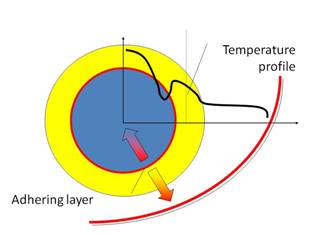

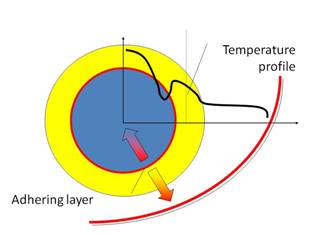

Among the parameters, temperature has a choice place. It influences viscosity, surface tension, drying or crystallisation behaviour. Ultimately, it influences the coating rate (thickness, weight gain) and coating resistance. It therefore influences the degree of clogging of product and ingredient in the system.

For example, fat will tend to set preferably on a cool product if the system wall is kept at a higher temperature.

The influence of some phenomena and their parameters is critical: crystallisation, water removal (drying), glass transition, viscosity, or surface tension.

Among the parameters, temperature has a choice place. It influences viscosity, surface tension, drying or crystallisation behaviour. Ultimately, it influences the coating rate (thickness, weight gain) and coating resistance. It therefore influences the degree of clogging of product and ingredient in the system.

For example, fat will tend to set preferably on a cool product if the system wall is kept at a higher temperature.

Given the number of operations and steps, a coating process can be an extensive process considered as a whole. The process core machine requires peripherals to serve it. A few frequent ones are listed for information.

* Storage

* Ingredient preparation

* Product feeding and metering

* Ingredient dosing

* Filtration or sieving

* Application system

* Recycling

Given the number of operations and steps, a coating process can be an extensive process considered as a whole. The process core machine requires peripherals to serve it. A few frequent ones are listed for information.

* Storage

* Ingredient preparation

* Product feeding and metering

* Ingredient dosing

* Filtration or sieving

* Application system

* Recycling

Coating

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. Pow ...

designates an operation as much as the result of it: the application of a layer and the layer itself. Coating takes different meanings depending on the industry concerned.

Definitions

This article concerns coating applications in the food industry. There are many similarities between coating processes and numerous examples oftechnology transfer

Technology transfer (TT), also called transfer of technology (TOT), is the process of transferring (disseminating) technology from the person or organization that owns or holds it to another person or organization, in an attempt to transform invent ...

to and from the food industry.

Coating in the food industry is the application of a layer of liquids or solids onto a product. The operation essentially relies on mechanical energy. It consists mostly in setting the product particles in motion and simultaneously applying the coating ingredient in a certain pattern to expose one to the other. It involves such phenomena as adhesion

Adhesion is the tendency of dissimilar particles or surfaces to cling to one another ( cohesion refers to the tendency of similar or identical particles/surfaces to cling to one another).

The forces that cause adhesion and cohesion can b ...

, friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of ...

, viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inte ...

, surface tension and crystallisation

Crystallization is the process by which solid forms, where the atoms or molecules are highly organized into a structure known as a crystal. Some ways by which crystals form are precipitating from a solution, freezing, or more rarely deposi ...

. Food coating is not a “hard” science such as drying

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid or liquid. This process is often used as a final production step before selling or packaging products. To be consider ...

or cooling

Cooling is removal of heat, usually resulting in a lower temperature and/or phase change. Temperature lowering achieved by any other means may also be called cooling.ASHRAE Terminology, https://www.ashrae.org/technical-resources/free-resources/as ...

, which can be described by equations and are predictable. Food coating is rather a “soft” knowledge derived from the accumulation of know-how. One reason is that the product and the ingredients considered have complex characteristics, variations and interactions.

Encapsulation is the application of a liquid layer to very small particles. It relies on an array of principles: entrapping a molecule inside a matrix

Matrix most commonly refers to:

* ''The Matrix'' (franchise), an American media franchise

** ''The Matrix'', a 1999 science-fiction action film

** "The Matrix", a fictional setting, a virtual reality environment, within ''The Matrix'' (franchis ...

, chemical bond

A chemical bond is a lasting attraction between atoms or ions that enables the formation of molecules and crystals. The bond may result from the electrostatic force between oppositely charged ions as in ionic bonds, or through the sharing of ...

ing, and polymerisation

In polymer chemistry, polymerization (American English), or polymerisation (British English), is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many for ...

. Encapsulation aims at the protection and controlled release of active molecules when immersed in an environment. As a rule of thumb, particle size

Particle size is a notion introduced for comparing dimensions of solid particles ('' flecks''), liquid particles ('' droplets''), or gaseous particles ('' bubbles''). The notion of particle size applies to particles in colloids, in ecology, in ...

can discriminate between “encapsulation” (below 300 µm to 1000 µm) and “food coating” (above this limit). Mere mechanical movement is not adequate and sufficient to fulfill the proper coating of minute particles.

IQF

Individual Quick Freezing, usually abbreviated IQF, is a descriptive term for freezing methods used in the food processing industry. The food is in individual pieces, and is frozen quickly. Products commonly frozen with IQF technologies are typical ...

vegetables coated with cream

File:Suikerboon-2.JPG, Sugar-coated dragees

Objectives of coating

Coatings can be added for the enhancement oforganoleptic

Organoleptic properties are the aspects of food, water or other substances that create an individual experience via the senses—including taste, sight, smell, and touch.

USDA uses

In traditional U.S. Department of Agriculture meat and poul ...

properties of a food product.

Appearance and palatability can be improved by adding color (white dragee, brown chocolate), changing the surface aspect (glazed sweets or rough, crispy nuggets); changing or adding tastes (sweet dragee, salted snack) or flavours (fruit-glazed sweet goods), or texture (breaded crispy nuggets).

Coatings also can be used to add vitamins and minerals (enriched white rice) or food energy.

Coating conveys functional properties, such as particle separation (oiled dry fruit, shredded cheese), antioxidant effect (fruit cubes), or a barrier effect ater migration between a layer of ice cream and a biscuit (cookie) or against moisture loss of chewing gum Barrier effects are often difficult to achieve.

An ingredient may be cheaper than the product it coats and thus allows for a slight cost reduction.

The coating process

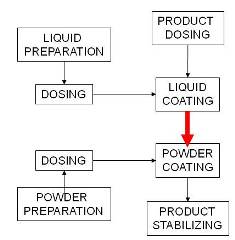

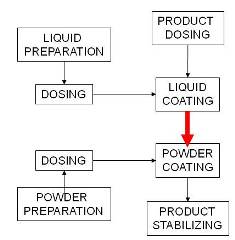

The coating process begins with the application of the coating on the food product, but the end product must be stable throughout its shelf life. Therefore, a coating process is completed by a stabilizing process, either by freezing, cooling, heating or drying. The sequences of this process are: #Application: To apply minute quantities of an ingredient, spraying is used to disperse it first, instead of just pouring it. This hastens the dispersion on the whole surface of the product. For larger ratios of coating to substrate, mixing or dipping can be used. Multiple stages also can be used; breaded meats, for example, may have a dry application (predust) followed by a wet batter dip and then another dry crumb application. #Adhesion: the coating must adhere to the product, meaning there must be a degree of affinity between the ingredient and the product. #Coalescence: in case of a liquid, the multiple droplets may merge to form a uniform continuous layer. Characteristics of the ingredient in relation to the product, such as viscosity and surface tension associated to a mechanical effect (friction) are critical. #Stabilisation : depending on the nature of the coating ingredient(s) and substrate product, the ingredient is stabilised by elimination of the solvent (drying and evaporation of water, alcohol), crystallisation (sugar crystallises when water is evaporated, fat crystallises when cooled), or thermal treatment (proteins set irreversibly when heated). A coating process can be broken into the following elements:

* Inputs: base product, additives and ingredients

* Additional flows: air as a carrier of product or ingredient, or for drying, energy in a mechanical (agitation, transfer, friction) or a thermal form (convection, conduction or radiation heating)

* Outputs: end product, excess of coating ingredient, lost or to be recycled

Collaterals occur along the process:

* Breakage of product

* Generation of ''fines'' (small particles)

* Agglomeration of products

* Clogging of system surfaces with product or ingredient

* Airborne pollution, volatile organic component

These effects generally are to be avoided unless the end product is made more desirable.

Parameters affecting the system are listed by origin:

This first set of criteria governs the choice of the coating ingredient. The coating consists either in a single ingredient or a mix. This mix has different physical forms: solution, emulsion, suspension, powder, etc. It has its own characteristics. In addition, a fluid may be required such as spraying, cooling, heating or drying air.

The combination of the above characteristics drives the choice of the process principle. It has then to be precisely described.

The selection of the proper process and its control rely on the gathering of precise and reliable information.

A coating process can be broken into the following elements:

* Inputs: base product, additives and ingredients

* Additional flows: air as a carrier of product or ingredient, or for drying, energy in a mechanical (agitation, transfer, friction) or a thermal form (convection, conduction or radiation heating)

* Outputs: end product, excess of coating ingredient, lost or to be recycled

Collaterals occur along the process:

* Breakage of product

* Generation of ''fines'' (small particles)

* Agglomeration of products

* Clogging of system surfaces with product or ingredient

* Airborne pollution, volatile organic component

These effects generally are to be avoided unless the end product is made more desirable.

Parameters affecting the system are listed by origin:

This first set of criteria governs the choice of the coating ingredient. The coating consists either in a single ingredient or a mix. This mix has different physical forms: solution, emulsion, suspension, powder, etc. It has its own characteristics. In addition, a fluid may be required such as spraying, cooling, heating or drying air.

The combination of the above characteristics drives the choice of the process principle. It has then to be precisely described.

The selection of the proper process and its control rely on the gathering of precise and reliable information.

The influence of some phenomena and their parameters is critical: crystallisation, water removal (drying), glass transition, viscosity, or surface tension.

Among the parameters, temperature has a choice place. It influences viscosity, surface tension, drying or crystallisation behaviour. Ultimately, it influences the coating rate (thickness, weight gain) and coating resistance. It therefore influences the degree of clogging of product and ingredient in the system.

For example, fat will tend to set preferably on a cool product if the system wall is kept at a higher temperature.

The influence of some phenomena and their parameters is critical: crystallisation, water removal (drying), glass transition, viscosity, or surface tension.

Among the parameters, temperature has a choice place. It influences viscosity, surface tension, drying or crystallisation behaviour. Ultimately, it influences the coating rate (thickness, weight gain) and coating resistance. It therefore influences the degree of clogging of product and ingredient in the system.

For example, fat will tend to set preferably on a cool product if the system wall is kept at a higher temperature.

Practice

Coating ingredients

Coating techniques

For the sake of classification, two categories can be split easily into batch or continuous processes. Then, the categories can be refined according to the way the product is set in motion and the ingredient applied. Then, techniques allow either for just coating or can combine coating and setting in the same equipment. Criteria for the selection of a technique * Base product characteristics: shape, size, bulk density. Size is the first criterion. * Mechanical resistance of the base product * Final thickness of the coating layer * Complete/partial, top/side/bottom coating * Number of sequences to repeat * Processing time for each sequence * Setting mode: drying, cooling, freezing * Capacity * Preferred batch or continuous system Comparison batch vs. Continuous The demand for higher yields makes production managers want to shift from manual batch to continuous automated systems. One has to consider the pros and contras prior to go for a costly and risky decision.Peripherals

Given the number of operations and steps, a coating process can be an extensive process considered as a whole. The process core machine requires peripherals to serve it. A few frequent ones are listed for information.

* Storage

* Ingredient preparation

* Product feeding and metering

* Ingredient dosing

* Filtration or sieving

* Application system

* Recycling

Given the number of operations and steps, a coating process can be an extensive process considered as a whole. The process core machine requires peripherals to serve it. A few frequent ones are listed for information.

* Storage

* Ingredient preparation

* Product feeding and metering

* Ingredient dosing

* Filtration or sieving

* Application system

* Recycling

Measures

Test results can be immediately evaluated (visual aspect) but are preferably assessed by careful measures : to allow monitoring, to agree on commissioning, to certify conformity with customer requirements. Typical measures : * Optical : colour, microscopy (homogeneity, thickness), image analysis * Weighing : weighing before and after treatment, weighing between batches or individual particles * Specific measurements according to target : compaction, barrier propertySee also

* Food processingReferences

{{DEFAULTSORT:Food Coating Coatings Food processing